CNC Machined from C360 brass to original specifications to ensure proper fitment and factory look. Equivalent to the AF440 with superior quality yet available at almost half the cost. Made in the USA

“Top notch quality at half the price. No leaks like some found on ebay”

“Top notch quality at half the price. No leaks like some found on ebay”

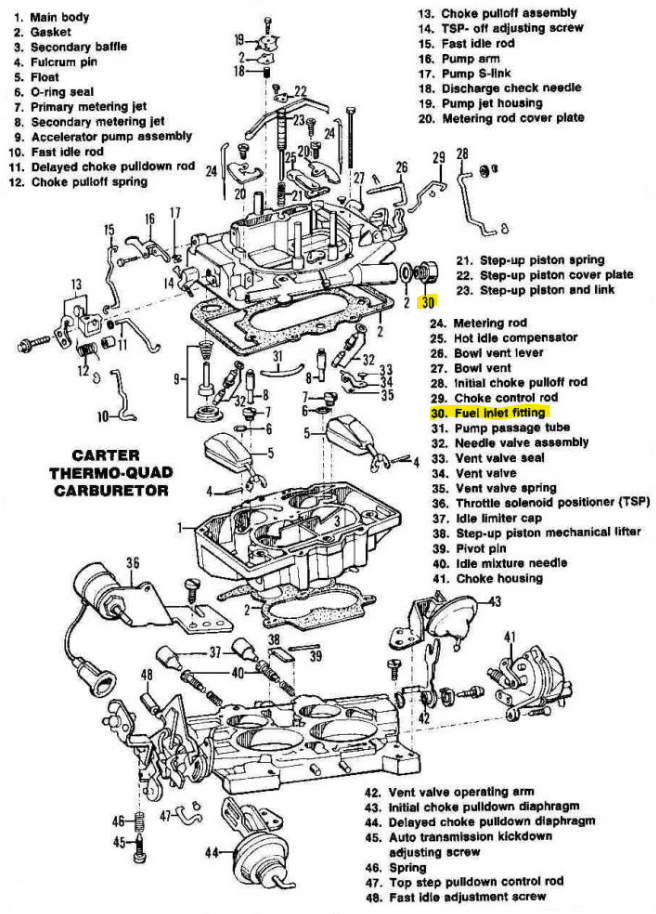

The 1/2″-20 and 5/8″-20 fuel inlet fittings refer to specific sizes of threads used in fuel line connections, particularly in automotive and machinery applications. These fittings play a crucial role in creating a secure and leak-proof connection for the flow of fuel, which is why their specification and compatibility with SAE standards are important.

These types of fittings are often sourced through automotive parts suppliers, hardware stores specializing in fuel line components, or industrial supply shops. Proper handling, correct torque application, and ensuring material compatibility are all important to maintain safety and reliability when using these fittings.

We noticed you're visiting from Canada. We've updated our prices to Canadian dollar for your shopping convenience. Use United States (US) dollar instead. Dismiss